Particle Size Reduction粒径减小

Our high pressure, high shear, technology excels at producing the smallest, most uniform particle sizes, with tight distributions, for Lab scale projects up to production systems with repeatable results.

Our Homogenizing systems are highly efficient at producing particles sizes in the range from a few nanometers to a few micrometers with the following important parameters:

Tight distribution - most of the droplets at or below the target size and no "tails" on the distribution graph.

The smallest size - smallest ratio of droplet surface area to droplet volume.

Particle Size Reduction - our High Pressure Homogenizers

Sophisticated temperature control systems, including pre- and post-cooling or heating, to preserve product quality and purity.

Ultra high pressures to 60,000 psi (4200 bar) and processing from 1 ml, e.g. for Lab R&D, to in excess of 1000 l/hour for production systems.

Our systems are easy to scale-up from Lab R&D to full production flow rates.

High operating reliability resulting in low on-going ownership and maintenance costs.

Benefits of Particle Size Reduction

Increased bioavailability and efficacy of the active active ingredient in the drug or product.

Improvements in product taste, colour, flowability and chemical reaction.

Higher product stability resulting in increased storage life.

Minimization or elimination of contamination.

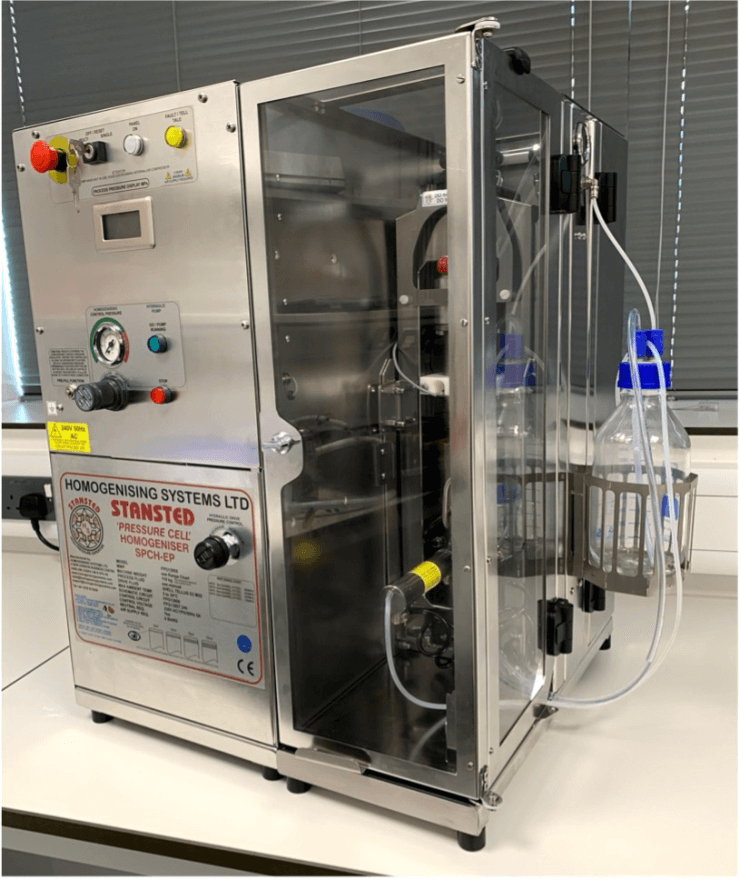

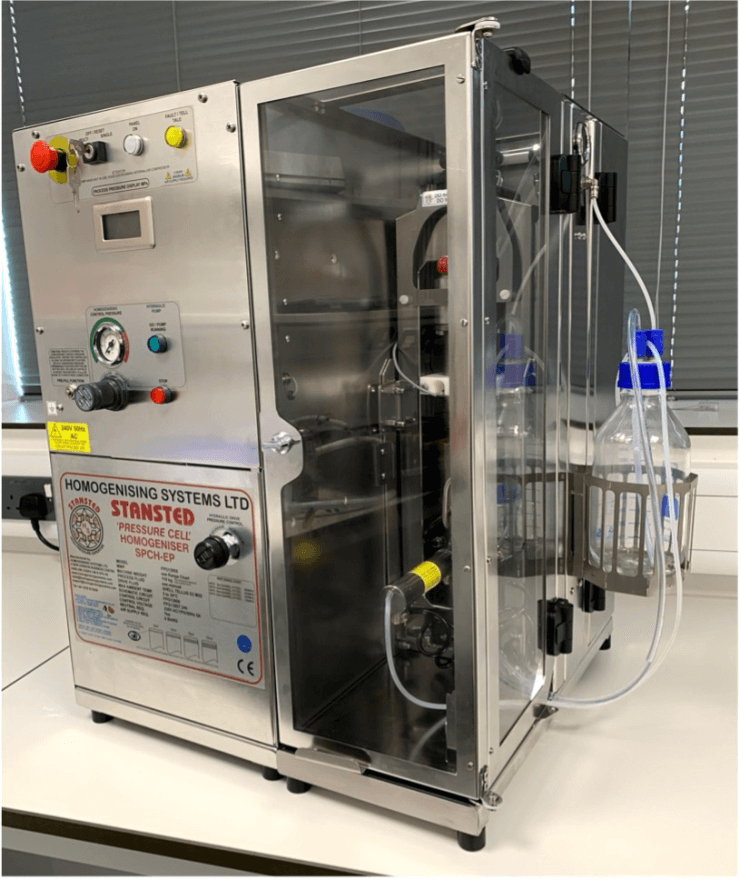

Laboratory / Bench-top

Up to 16 l/h. Processing cells from 1m to 35ml. For R&D and small volumes.

Pilot - smaller scale Production

Up to 125 l/hr for smaller scale production.

Production Scale

With flow rates up to 1000 l/hr (264 US Gallons). Unrivalled performance.

Benefits described above can be achieved when our reliable high pressure pumping system generates up to 60,000 psi / 4200 bar (highest available) to force the product stream into the processing section which results in:

1. Impact on entry to the valve (piston gap) or micro-channel section.

2. Very high liquid shear in this section.

3. Sudden pressure drop upon discharge.

我们的高压、高剪切技术擅长生产最小、最均匀的颗粒尺寸,分布紧密,为实验室规模的项目生产系统提供可重复的结果。

我们的均质系统在生产从几纳米到几微米的颗粒时非常高效,并具有以下重要参数:

紧密分布-大多数液滴达到或低于目标尺寸,在分布图上没有“尾巴”。

最小尺寸-液滴表面积与液滴体积的最小比值。

粒径减小-我们的高压均质机

复杂的温度控制系统,包括前后冷却或加热,以保持产品质量和纯度。

超高压力达到60000 psi (4200 bar),处理从1ml,例如实验室研发,到超过1000 l/小时的生产系统。

我们的系统很容易从实验室研发扩展到全生产流程。

高的运行可靠性导致低的持续所有权和维护成本。

粒径减小的好处

提高药物或产品中活性成分的生物利用度和功效。

改善产品的口感,颜色,流动性和化学反应。

产品稳定性高,储存寿命长。

减少或消除污染

实验室/桌上型

高达16升/小时。处理细胞从1米到35毫升。用于研发和小批量。

颗粒尺寸缩小实验室均质机的图像。

中试-小规模生产

高达125升/小时的小规模生产。

粒径缩小图像中试型高压均质机。

生产规模

流速高达1000升/小时(264美国加仑)。无与伦比的性能。

粒径缩小生产规模均质机图像。

当我们可靠的高压泵系统产生高达60000 psi / 4200 bar(最高)的压力时,可以实现上述效益,迫使产品流进入加工部分,导致:

1. 对进入阀门(活塞间隙)或微通道段的影响。

2. 这部分的液体剪切非常高。

3.放电时突然压降。